「紙とFAXでやりとりをしている」という話はあらゆる業界で聞くが、アパレル産業はその最たるものだろう。取引先が多く関係者も多いため、コミュニケーションの複雑さは想像を絶する。

The service that tries to IT-ize such apparel industry " AYATORI (Ayatori), a management tool specialized for apparel. By using AYATORI, communication can be centrally managed, business errors associated with complexity can be expected, and business efficiency can be improved.

This time, we talked to Mr. Fukaya, the managing director of DeepValley Co., Ltd., who operates AYATORI.

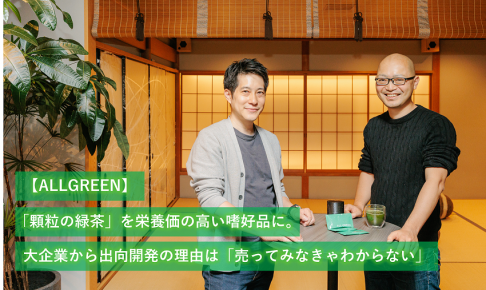

Collectively manage complex apparel supply chains

The figure below was published by the Ministry of Economy, Trade and Industry in 2017 "Issues in the Japanese fashion industry and future responses" It is a part of the document. The figure on the left clearly shows that the apparel industry is in a complex supply chain environment. On the other hand, in the right figure, the IT platform environment is prepared, and all the parties have access to it to sort out the transaction.

(image: DeepValley)

The apparel industry's supply chain is very long and therefore has many people involved. Since each work is highly specialized, it is very difficult to understand the entire business flow, such as fabric, sewing, merchandising and sales.

So how do the apparel supply chain players manage it? It's amazingly analog. The apparel industry still communicates by phone and fax, and often stores information on paper.

When trying to make clothes, designers drop design ideas on paper (although there has recently been an increase in digital ones), which is the source of specifications. The image is that this will flow downstream in the supply chain, and the necessary items will be added by hand in each process.

However, as mentioned earlier, the apparel supply chain is very complex and managing specifications is very laborious. Because it is paper, it has to be filed and managed, and it takes time to search later. It may not be hard to imagine that writing is simply impossible to read because of handwriting, and it takes time to update information.

AYATORI, an apparel-specialized vertical SaaS that can centrally manage "communication" and "necessary information" in the apparel manufacturing process, is trying to create a hole in the supply chain management of such apparel industry.

AYATORI is a service that enables centralized management and communication of necessary information in processes. Items will be completed through communication, but if you access AYATORI, you will be able to obtain information of specifications, that is, data of design drawings, fabrics and patterns. (Mr. Fukaya, and so on)

Available parties are available free of charge

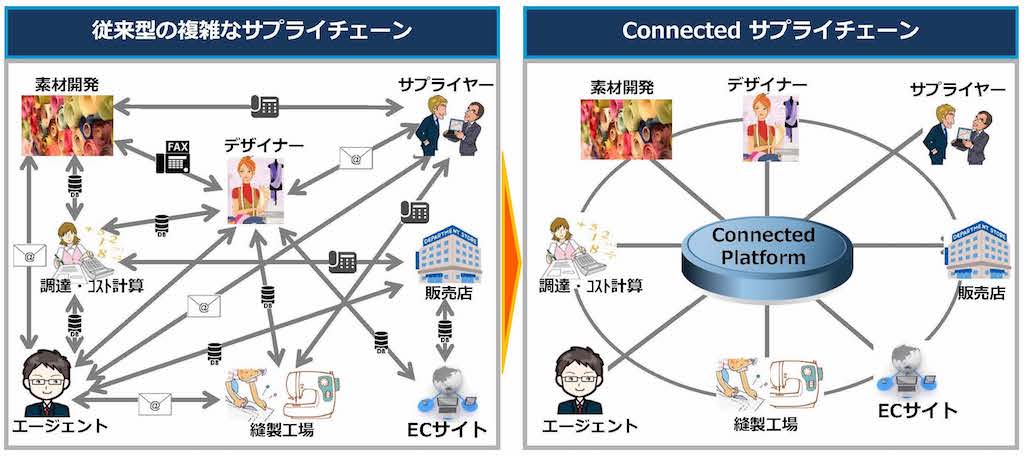

According to Fukaya, a management system has also appeared as a service of FashionTech (Fashion Tech), but many of them are services after products are made, and there is no production management system. Conversely, AYATORI is a service for people in charge of production management. By using AYATORI, it is assumed that the production manager will be used by the designers and MD personnel around it.

(image: DeepValley)

Naturally, the supply chain is not complete only by the company itself, but multiple companies are involved. Therefore, how all involved use AYATORI is the key to the efficiency of the entire supply chain. At that point, AYATORI is a growth hack that makes the monetization method unique.

AYATORIのマネタイズは月額課金のサブスクリプションモデルだ。ただお金を支払うのはユーザ全員ではなく、「プロダクトを最初に登録するプレイヤー」だけ。たとえばあるブランドがプロジェクトでAYATORIを使いはじめ、他のプレイヤーを招待すれば、招待された側はこのプロジェクト内なら支払いなしにAYATORIを利用できる、という仕組みだ(ただし無料ユーザは一部機能制限がある)。

The invited players can use AYATORI free of charge, but they have to be paid members if they want to use them in other projects. AYATORI aims to increase the number of users in this way.

As introduced above, AYATORI can be used by anyone in the supply chain, but AYATORI's first target was apparel that is said to be relatively balanced in the supply chain. However, when I tried to release it, it was unexpectedly "OEM supplier" that there were many inquiries.

As introduced above, AYATORI can be used by anyone in the supply chain, but AYATORI's first target was apparel that is said to be relatively balanced in the supply chain. However, when I tried to release it, it was unexpectedly "OEM supplier" that there were many inquiries.

When I released it, there were a lot of inquiries from OEMs that were actually in the middle. When I was listening to the story, people in the river got an impression that they were doing a little bit of work in some way. Because that also adjusted this, it would often be cumbersome to manage, and there was a strong need to streamline this work.

Create multiple projects within the same product project

I would like to look at the specific functions of AYATORI. According to Fukaya, the function of AYATORI can be described briefly as "like adding mail and LINE" or as "GitHub (*) for making things."

(*) Version control tool for software development used by engineers

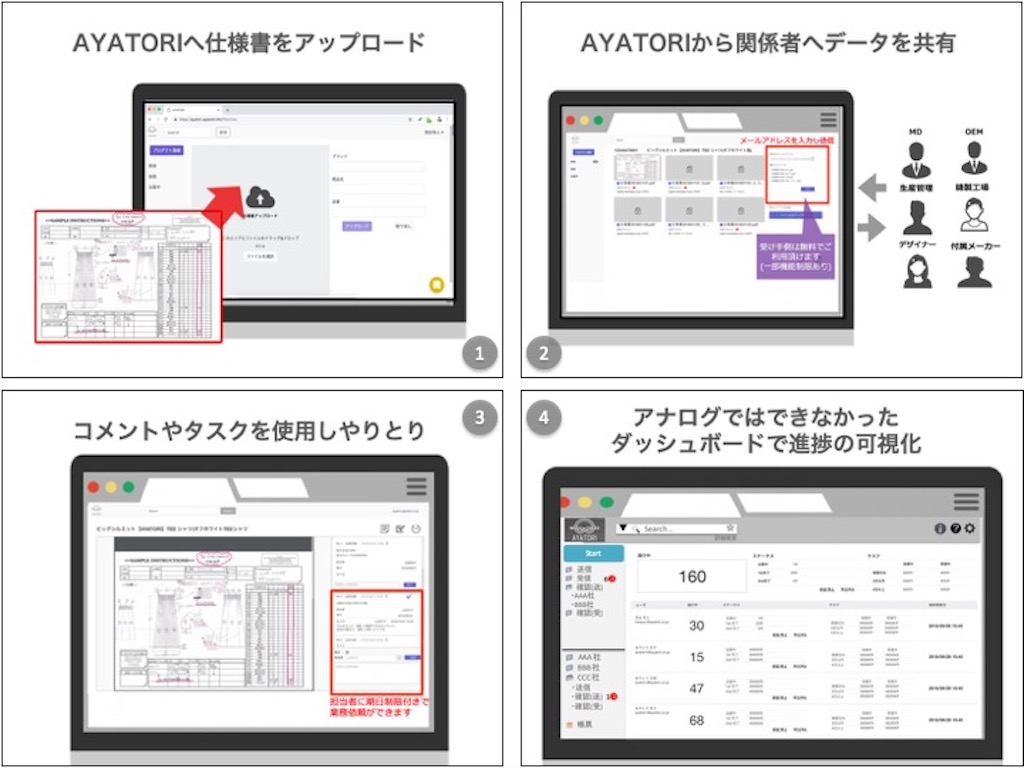

Once you have a specification, upload it to AYATORI. Invite interested parties to create a group (like LINE) and start communicating with "This specification is complete" "What will you do with the samples?" It can manage tasks, and it can also manage progress using dashboards.

(image: DeepValley)

The point of AYATORI is to be able to create multiple groups in any specification. The group A is the group that communicates with the sewing factory, the group B is the group that communicates with the patternner to make the pattern data based on the specifications, and the group C is the group that shares information internally. Again, the apparel supply chain is long and complex. So even if you make a product, not everyone is involved all the time. Therefore, it is a function that is necessary because it is necessary to limit players involved in each process.

Making the entire supply chain more efficient increases the time to face one

At the apparel site, where specifications and progress are managed by paper, it takes time to search for evidence and check the progress of work. The benefit that users can get from using AYATORI in such situations is the "efficiency" of all their work.

If you manage specifications by paper and communicate with various systems such as e-mail, LINE, and telephone, the situation will be as follows in the field.

When asked by the boss, "What happened?", The person in charge looks for a file with many lines. Even if you check the specifications from the file (and sometimes it can not be deciphered because of handwriting), there is no information said to you, so search the mail. Still it can not be found "Ah, it's LINE" and confirms LINE of personal account. Still, I can not understand the situation (there is also a problem that sharing information is difficult in personal LINE). I can't help but call him. It goes without saying that the work ahead will stop during that time.

At that point AYATORI information is consolidated and manageable. Sharing among personnel is easy and time loss is reduced.  Naturally, if parts of the supply chain are streamlined, the entire supply chain will also be streamlined. Therefore, it is possible to increase the production volume, reduce the working time, and increase the time for one delivery more than before.

Naturally, if parts of the supply chain are streamlined, the entire supply chain will also be streamlined. Therefore, it is possible to increase the production volume, reduce the working time, and increase the time for one delivery more than before.

If the entire supply chain is made more efficient, it has the advantage of increasing production volume and shortening time, but I think it is possible to create something even if you put it in your mind. Not only the craftsman but also the trading company and the OEM manufacturer spend time to prevent trouble, try to search other manufacturers for making better products, and ask them to make a factory like this one by one I think I will be able to do it.

The disadvantage of using time extra is that the environment "let's make things right" is forced into being. It would be nice if AYATORI would be a clue to the solution.

Support using a simple UI and technology

As I explained, AYATORI tries to turn the mainstream apparel industry into IT by analog management, but is it that existing players will not refuse to digitize?

This point Fukaya also says, "There is an aspect I was worried at first." However, in recent years, ZOZO, which has become the eye of the apparel industry, and digital services developed by startups are also increasing. Also, with the spread of smartphones, craftsmen use fax at work, but it is not uncommon for private exchanges to be LINE. In that sense, it seems that there is less to be hairy hate just because it is digital.

However, the more complex the system, the more difficult it is to manage. So, AYATORI is stuck with a simple UI that says, "If you can use mail and LINE, you can also use AYATORI".  In terms of structure, AYATORI works as a semi-forced user in a sense in a sense. A paid user who has made a decision to become a user of AYATORI may still not be able to use AYATORI for free users.

In terms of structure, AYATORI works as a semi-forced user in a sense in a sense. A paid user who has made a decision to become a user of AYATORI may still not be able to use AYATORI for free users.

AYATORIでは、無料のユーザも有料のユーザと同レベルでサポートするという意思決定をしています。とはいえイチからすべてを説明するわけではなく、モニタリングしながらチャットボットなどもうまく使いながら、全てのユーザをサポートしていく予定です。

AYATORIの仕組みはメールと似ているので、メッセージがあるのに開封をしていないといったことがユーザごとにわかる。そのときにボットから「大丈夫ですか」と聞いたり、To Doが消化されていなかったらリマインドする、といった方法でユーザをサポートしていくようだ。

Looking at the industry other than apparel, we can change the apparel industry

AYATORI is a toB service that solves the challenges of the apparel industry. Therefore, knowledge of the apparel industry would be advantageous for service development. However, having experience in the apparel industry may now have no knowledge of IT. Although the era of permanent employment is virtually over, Japan is still not a common job changer compared to other countries, and the case of multiple industry knowledge is still not common. Therefore, having knowledge of apparel and IT will be rare.

Mr. Fukaya changed his job in the IT industry after experiencing the apparel industry. The experience of delaying the digitization of the apparel industry by looking at the outside industry makes the entrepreneurial decision.

After working a few times, I worked in the apparel industry for about 10 years. However, after that, I felt discomfort or a limit, and I thought that I would not learn IT, so I switched to an IT venture.

Since I was in sales, I studied about other industries and technologies, but when I looked back on it, I found that the apparel industry was a great analog.

Mr. Fukaya was most shocked by the food and drink platform service. Eating and drinking are the same as apparel, and it is an industry that is often cited as IT is not in progress. Despite this, with some services, the various platforms such as store purchasing, ordering, billing management, etc. were platformed, and each business was coordinated well.

The apparel industry is likely to build a similar mechanism, but there is no such platform. Mr. Fukaya who acquired the knowledge of apparel and IT decided on entrepreneurship, also feeling the crustal movement occurring in other industries. Established DeepValley and embarked on the development of AYATORI to become a platform service for the apparel industry.

Aim to unify disparate specifications

In March 2019, DeepValley announced the following press release.

Specifications in the apparel industry are not uniform and companies use different formats. If the format is different, it will be difficult to find out the information, and the necessary information may be missing. It can not be overlooked that this is creating industry inefficiency.  サービス展開してからAYATORIがヒアリングする中で判明したのは、特殊な仕様書が必要な場面は非常に少ないということだ。実際ステークホルダーに話を聞いても、とくにこだわりのあるプレイヤーは少なかった。そこでDeepValley社は、統一フォーマットとして使える最大公約数的な仕様書フォーマットを公開。多くのプレイヤーに使ってもらうため、無料で公開するに至った。

サービス展開してからAYATORIがヒアリングする中で判明したのは、特殊な仕様書が必要な場面は非常に少ないということだ。実際ステークホルダーに話を聞いても、とくにこだわりのあるプレイヤーは少なかった。そこでDeepValley社は、統一フォーマットとして使える最大公約数的な仕様書フォーマットを公開。多くのプレイヤーに使ってもらうため、無料で公開するに至った。

As I mentioned earlier, the unified format is overwhelmingly more convenient if you read the specifications. The fact that they are easy to read increases the productivity of Japan, to put it roughly.

Of course, there is still a problem that the pattern data can not be handled if it is only the one that has been published. However, I got it based on this, and I thought that it would be better for the entire apparel industry to become smoother by reducing omissions, and it came to be released.

Of course, there is no doubt that there is a merit as AYATORI if it is a uniform format. Even if the format is uniform, it is easy to digitize the contents of the specification, because it is possible to know what information is written in even where it is read by OCR. If data conversion is possible, multilingualization may occur during overseas production, and conversely, it may be easier to place an order from a foreign brand to Japan.

Data and AI may support the apparel industry

If AYATORI is operated, data of specifications and data of communication based on the specifications will be collected in the future. "We will work on data analysis in the future, but at the moment we are focusing on service creation," but there is a visible worldview. It is analysis of design and utilization of AI.

In apparel, design x AI is often the topic of climbing. However, at present, I feel that there are many arguments that it is difficult to convert design into data. The reason is that the design (specification) is analog and there is no data to be learned by the AI. Even though there is a final clothes image, the specifications that are the design drawings are not data that AI can capture.

However, if AYATORI succeeds in converting the specification and design into data and can analyze the image of the clothes and the design drawings, there is a possibility that the AI can be predicted.

Of course there is also the possibility that AI will play an active part, but since fashion is also a counter culture, I think that things that are contrary to AI's suggestions are sometimes noticed.

However, for example, when you decide on the design in the specification and decide on the fabric, it is calculated that "This is the percentage of your brand that sells in the brand." Or "This specification is convenient to fasten here." Is convenient. AYATORI wants to look at that.

You may also find that "it's easy to tear with this material." It's too late to be in trouble after trying to make it, so if you know it in advance, this also leads to more efficient work.

Finally, I asked Fukaya for a message to the apparel industry.

Finally, I asked Fukaya for a message to the apparel industry.

I said that AI is a platform, but fashion requires a sense, sense, and accumulated technology, and technology should help to focus on them. Still, I may be disliked just because it's new and I don't know. We love the fashion and apparel industry, but I think it is not good for the whole industry to go into decline without making progress.

That is why DeepValley's mission is to change the industry over a lifetime through AYATORI in order to love it. Thank you for your support.

AYATORI tries to eliminate the troubles of the apparel industry and prepare an environment where it is possible to make better products. The current focus is on improving work efficiency and communication, but in the future it has the potential to further contribute to the industry using specification data. Apparel officials should pay attention to AYATORI.

代表者:深谷 玲人(Fukaya Reito)

所在地:東京

設立日:2018年5月

URL :https://www.deepvalley.co.jp/

※情報は記事公開時点のものです。

インタビューはpodcastでも配信しています

ポッドキャストで取材時のインタビューを配信しています。

制作チーム

peitaro / Notomi Jumpei

Representative CEO of pilot boat, LLC

Born in 1987. Graduated from Business Administration, Meiji University, graduate school of accounting, Waseda University. Passed the Certified Public Accountant examination while in the university. After engaging in auditing accounting with a major audit firm, participated in a venture support company and produced more than 300 pitch / event. In 2017 independently established a joint venture company "pilot boat" and continues to support startups. Pilot boat, runs media which introduces startups in long interviews and conducts toC venture presentation event "sprout", and other startup events. Speciality is Fashion, beauty, technology, lifestyle and culture system toC service. Also serve as a writer on startup and innovation-related theme in various media and consults major companies for open innovation.

Twitter: @ jumpei_notomi

森田大翔(TAISHO) 写真家/映像作家

【写真】 雑誌やWeb広告など、人物を中心に撮影。イベント撮影や企業様の採用写真(Wantedlyなど)も多く撮影。

【映像】 企業様を対象にしたドキュメンタリー映像やメイキング映像が多く、ドローンを使用した撮影も可能。(CM撮影など)

【受賞歴】 “The new generation digital photo contest 2013” 最優秀賞受賞

The latest information is LINE@!

We announce you in LINE@ at article delivery. If you would like to be notified of the update of the article, please follow LINE@! ![]()